Combine Field Support with In-House Services

When you combine our field service with our respected in-house services, it’s a one-two punch that strengthens your project. All field operations at Edmonton Exchanger are fully supported by in-house services that can be obtained individually or as a complete service package:

- Project Management

- Estimating

- Safety Management

- Procurement

- Subcontract Coordination

- Large-scale Machining

Planning, Scheduling, Reporting with the Latest Software Technology

No matter what your project scope is, we can provide accurate and detailed planning, scheduling, and reporting. We offer in-house scheduling, detailed planning and custom reporting services by means of state-of-the-art software technology. For project scheduling we employ the industry standard Primavera scheduling software.

In addition, cost control functions can be provided to complement our scheduling capabilities. Planning and scheduling services can be provided as a stand-alone service contract or as a support service.

Quality Control

Standards available include:

- ASME Section 1 – Power Boilers

- ASME Section VIII Div. 1 – Pressure Vessels

- ASME Section VIII Div. 2 – Pressure Vessels

- ASME B31.1 Power Piping

- ASME B31.1 Boiler External Piping

- ASME B31.3 Process Piping

- CWB 47.1 Level 2 Structural

- National Board

Steel Fabrication Plant Support Including Emergency Repairs

Go beyond the basics with a full menu of steel fabrication support. Our Steel Fabrication Plant provides full support and emergency repair services to our field operations. This facility features services such as head forming, plate rolling, profile cutting, custom stress relieving, and large-scale machining. It is supported by a large plate inventory of pressure vessel quality carbon steel, stainless steel and chromium molybdenum steel.

Engineering Experts are at Your Service

Need engineering support as well? No problem. Our high-tech engineering capabilities allow us to provide complete in-house engineering support to our field operations. Additional support is provided for such applications as:

- Equipment Rigging Analyses

- Alterations to ASME Sec. VIII Div. 1 and 2

- Vessel and Heat Exchanger Evaluations

- Vessel and Heat Exchanger Re-rates

Finite Element Stress Analyses

Finite Element Stress Analyses are available for such uses as SIF, and allowable load and stiffness determinations for vessel nozzles and fittings. Additional comparisons to traditional verification methods are also offered.

Bolted Joint Analysis

Gasket / stud / flange design checks to optimize design, and / or determine most suitable gasket and stud stress utilizing industry best practice.

Additional Field Support Services Available:

- Nondestructive Examination

- Weld Mapping

- Turnover Documents

- Bolt Torquing

- Field Machining

- Field Scanning

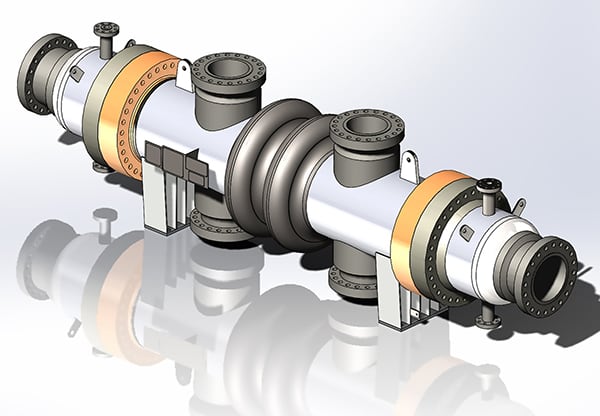

Engineering and Shop Fabrication Support for Rush Client Requests

This 31.75mm (1.25”) thick stainless expansion joint assembly was designed, formed and installed in two fixed tubesheet type BXM heat exchangers by Edmonton Exchanger. The design included consideration of all ASME Part UHX design conditions and FEA. The integral shell and tubeside was dis-assembled to fit and weld the newly designed and formed expansion joints. The tube to tubesheet joint welds were orbitally welded strength welds. The time to complete this project from the first client email, to the shipment of the fully retro-fitted, ABSA certified hydro-tested and inspected pair of exchangers was two months.